The abundance of all sorts of devices available around can make your head spin. Awesome inventions that make life easier just keep coming up. Whether it’s for personal or commercial use, the undeniable fact is that machines play an ever-increasing role in our lives. It seems that living without them sounds like an impossible thing to do these days. In this article, we will take a deep dive into the use of a particular type of device – an embedded system, that is. Curious to know the main attributes of such an embedded system or the areas in which it has been applied? Keep on reading!

The concept of ”embedded system” has a very broad meaning. In simple terms, it is a system dedicated to a solution or functionality that runs in some other, more extensive system. In such devices, reliability and timeframes for performing a specific task may be of great relevance at times. In most cases, it comprises hardware and software parts, along with specialized algorithms.

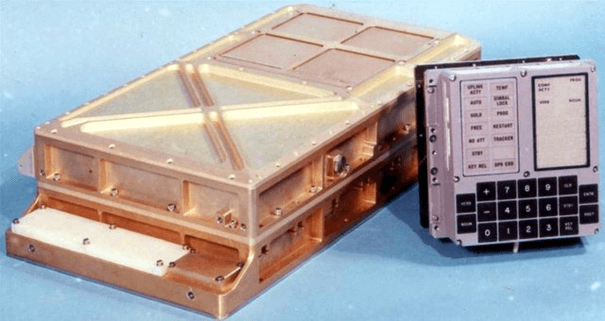

source: NASA Apollo Guidance Computer

The beginnings of embedded systems can be traced back to the second half of the 20th century. It was then that the ground-breaking Apollo 11 onboard computer was built. It was a breakthrough both in terms of construction and the software itself, since it had to deliver a lot of functionality with very little hardware resources. The device itself weighed 32 kg and offered 74 kB of permanent memory (ROM) and 4 kB of operating memory (RAM).

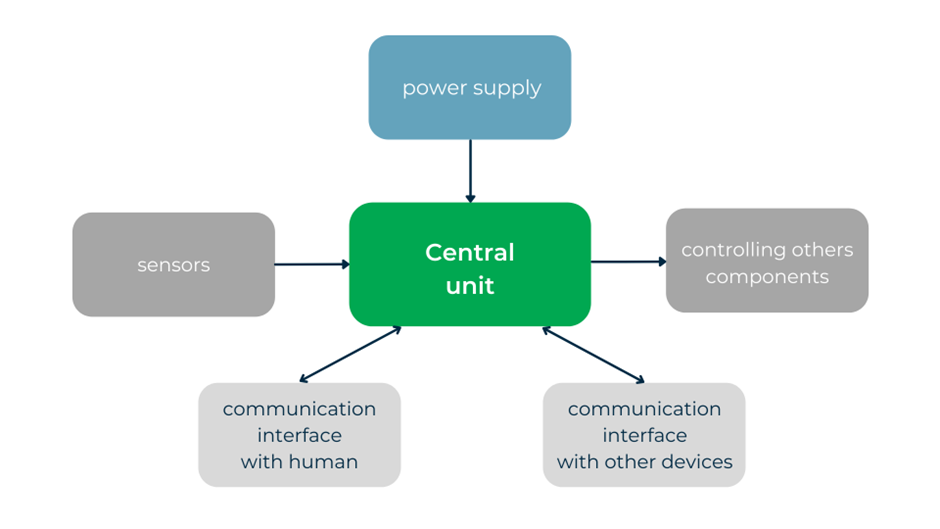

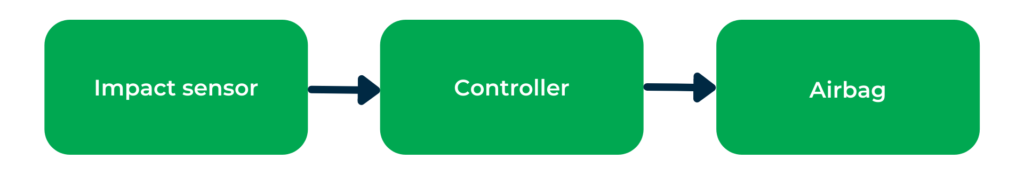

Embedded systems are currently on the rise and this market is set to register commendable growth over the coming years. Their capabilities far exceed those of their predecessors. Most of them are based on microcontrollers, i.e., integrated circuits containing CPU, memory, and peripheral interfaces. ASICs are developed to meet the needs of more demanding systems, as they are very powerful but relatively expensive to design. An embedded system can be illustrated schematically as the example below:

In a nutshell, a typical embedded system is a very simple device. Sensors measure size data, communication interfaces exchange the necessary data with other devices as well as with humans themselves (e.g. the display), and the power supply provides energy. On top of that, there are other modules that directly impact the operation of the entire device, such as an electromagnetic relay controller. So, in theory, it is technically a very simple device

To answer this question, one must first come up with an answer to another equally important prerogative.

How does an embedded system differ from a regular laptop/PC?

At first glance, there are only a few differences. Both systems have a central processing unit, memory, or peripherals. In fact, even a laptop seems to be a rather good solution in some cases, due to its portability. Unfortunately, what may seem sound at first glance, is not so after a more thorough analysis. And as always, the devil is in the detail.

An embedded system is geared towards a limited number of functionalities. It is designed so that a given task can be carried out within a strictly specified time, and reliability is at the highest possible level. The same cannot be said about typical home-office computers, where the predictability of task execution time does not configure much importance. Why? Because the programs tend to hang, and the whole system suffers from a blue screen after prolonged use without restarting. Additionally, power consumption plays an important parameter too.

Using a laptop, for instance, to measure voltage and transmit it to another system means we waste an exorbitant amount of energy. A well-designed embedded system can perform the same task using only a fraction of this power.

Embedded systems come with a huge range of possibilities. Everything here starts with the central unit used and the sensors, transducers, or communication interfaces connected to it. One can envisage a system with a highly sensitive digital brainwave transducer. Based on its measurements and programmed knowledge of the human brain, it will be able to classify changes in it – something akin to a thought decoder. Sounds great, right? So, why not?

A major limitation of embedded systems is the finite measurement capabilities of the components used. Well, at least for now. Each sensor or transducer has its own accuracy or maximum processing frequency. Bear in mind that certain constraints cannot be circumvented on the basis of the current technological level handled. Additionally, it may happen that a given parameter is very hard to measure, and the processing of the collected data poses many problems.

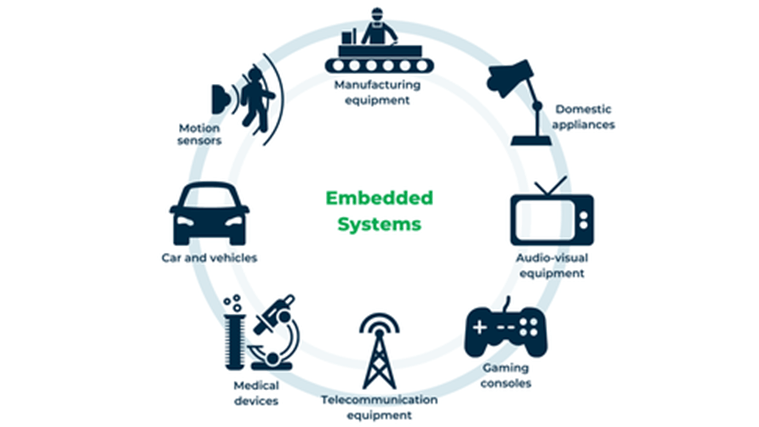

Embedded systems can be found virtually everywhere. In fact, it is hard to name an industry in which these devices are not relevant or their use would not come with tangible benefits. What can be said, almost for sure, is they will become indispensable in tackling the problems that will arise only in the future. The surging demand for specialized equipment is going strong and, overall, is not expected to diminish over time.

It cannot go unnoticed that modern cars are packed with electronics, though this is a very general way to put it. To be more precise, it should be said that modern cars are equipped with numerous built-in systems. Central locking, engine start system, power steering, air conditioning, or even all sorts of displays – these all run on embedded devices.

Every sub-system has to deliver a very high level of reliability and failure-free performance. In fact, the quality of the components installed in vehicles directly impacts human life. It is easy to picture what could happen if a car’s basic systems failed. An error in the central braking system would prevent effective braking, while a failure of the fuel system control unit could cause constant acceleration. In either case, these failures would most likely lead to disaster.

To mitigate errors in critical systems, they are subjected to stringent testing. These tests verify whether a component is able to run in a particular operating environment while providing the designed functionality. Think of an airbag system in a car as an example.

The signal from the impact sensor is routed to the controller, which then decides whether the cushion is fired. The system should be effective for relatively small impact forces as well as for larger ones. Plus, it needs to work within a sufficiently short period of time. Needless to say, all these parameters must be thoroughly tested.

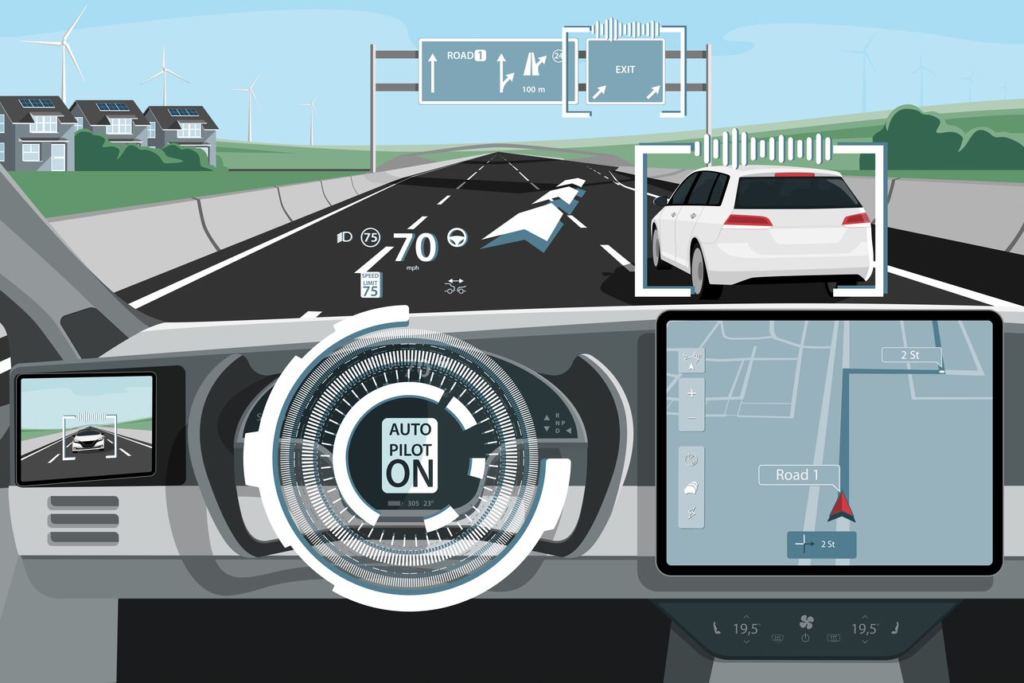

A slightly less critical (in terms of safety) but still quite exciting topic is in-car displays. These days, manufacturers are equipping cars with ever more perfect systems for visualizing important journey parameters.

Some rely on a single, large display on the dashboard for practically everything. Others opt for diversification and modernity by fitting HUD (head-up display) type displays. In Solwit, for one of our clients, we developed selected functionalities of such a platform and took part in creating the architecture of certain functionalities and launching a new prototype of the solution. Read more about the software development project for Graphics Display Controller in automotive.

Raise your hand if you haven’t heard of intelligent building. Anyone?! By “intelligent” we may imagine a building that will clean, cook dinner, or order groceries without human assistance. Additionally, it could come with the option to change its shape or design depending on the owner’s needs. Going further, such a dream smart home could be energy self-sufficient and climate-neutral.

Although such houses are still a long way off for us as humanity, progress along this road has been significant. Of course, all thanks to embedded systems. The more intelligent the home, the more such apparatuses can be found in it. Starting with such mundane things as the ability to control roller blinds via your phone, to artificial intelligence and biometric systems for the householders’ authentication. In the vast majority of cases, a term associated with building automation is, at some stage, an embedded system.

Even if the building was not originally designed for automation in the broad sense, the market is full of devices that allow you to upgrade your premises. Embedded systems for automatic lighting regulation, temperature and humidity control, or presence detection can all make a substantial difference to the comfort of living.

But, let’s not forget the downsides of such installations. The first is, of course, the cost, which is made up of the embedded systems themselves, additional cables, or future maintenance and repairs. The second is the risk of loss of privacy or security. The more digitalized the home, the more potential “gateways” for criminals. Hence why we need to keep the following aspects in mind as early as the embedded system design stage: authorization, access control, and encryption of communication.

In order to enhance the safety of residents’ lives, the world of embedded systems also comes with dedicated solutions. Ideally, we would like some sort of “thing” to detect a burglary, fire, or any other dangerous event on its own, and inform the relevant emergency services. One of the examples of a solution to the problem presented here is the AED.

The system constantly records the sound signal, then processes it and determines whether a dangerous event has occurred. If it finds that a hazardous activity has taken place, it triggers the alarm and notifies the relevant services or persons.

As we mentioned earlier, almost every sphere of life can be enhanced with the use of embedded systems. The case is no different when it comes to protecting and saving human lives.

In the whole process of treating a patient, a very important aspect is the correct diagnosis of an illness. In the case of a wrong diagnosis, the patient may take medication that might even harm them. In addition, time and money are wasted on this whole unnecessary process. So, the great news is that precisely the diagnosis is what can be aided by the embedded systems of the medical equipment.

An extremely good example is the technique of imaging objects with magnetic resonance. This device has been designed to give a very accurate mapping of a person’s internal organs in three-dimensional space. It features a number of high-precision sensors that continuously take the necessary measurements during the examination. These samples are then processed by one or more central units and, on this basis, form a three-dimensional image of the organ.

Once a disease has been correctly diagnosed, what comes is its treatment. Patient monitoring devices provide invaluable information about the current condition of the sufferer. With this data, doctors are in a position to react quickly to any sudden change and can alter the method of treatment at an early stage.

Something else that has become invaluable in the healthcare industry are devices that automatically dose medication to the patient. This is mutually beneficial. For starters, the medics can get some rest and the patient gets a tool to speed up recovery. Diabetes is an example of an illness that can benefit from this, and the insulin pump is an example of a device. In simple terms, the device consists of an insulin cup, a small pump, and sensors that precisely measure the dose of medication given. This small-sized embedded system measures the right amount of insulin and pumps it into the body through a small needle. Since this device is extremely handy, it is essential to bear in mind the responsibility it entails when designing it. Both the doctor and the patient will expect 100% reliability at all times. These devices are directly responsible for human health and life, which is why they must meet stringent medical standards. These standards in a way enforce the highest quality of the software and hardware platform of the device. Here at Solwit, we have witnessed this in numerous safety-critical projects and, in particular, when we were developing software for a device on which people’s lives heavily depend, namely the aforementioned insulin pump.

Up to this point, not once has the term IoT appeared, though it is very related to the title in the headline. The Internet of Things is a more diverse field than embedded systems and in general it refers to the structure of connections and how information is exchanged and processed between connected devices. An embedded system is not pure IoT. Instead, IoT describes how information is exchanged and processed by, among other things, connected embedded systems.

The application of IoT in the industry is especially noteworthy. In this field, maintaining the continuity of production is crucial, as each downtime means financial losses and is associated with a decrease in credibility for other companies. It is essential to keep monitoring the technical condition of production equipment and to predict any possible failures. A network of sensors comes in extremely handy in this process, collecting real-time information about the operating parameters of machines and, based on this information, being able to predict an imminent failure. A vibration sensor placed on a motor in a production line is a great example. By measuring the vibration, we are able to determine the degree of wear and tear of a critical part in the engine, and thus plan a repair before a breakdown occurs. This mitigates the risk of losing continuity in the production.

The industry is also fond of all kinds of optimization of production processes. Optimization is directly linked to reducing costs or increasing product quality, and this translates into higher revenues. By measuring the quality of the product itself, as well as of semi-finished products, we are quicker to determine all the “things that go wrong” in the entire process. The more parameters we measure, the more knowledge we gain over each stage of production. The greater knowledge can be leveraged to enhance the defective manufacturing phase. Data derived from the failure prevention system and data from the quality control system can be merged with the control system of the production equipment itself. By combining these, we end up with one giant IoT embedded system. Data from one system is incorporated into the control of another and vice versa. Then a truly intelligent factory can be said to be in place. Devices “talk” to each other and on the basis of this “talk” take action without human involvement. A human only controls the accuracy of the actions taken by the autonomous systems. Setting up a fully autonomous factory makes it a very daunting task, among other things, due to the need to find the right data processing models. Having data from each, even in the smallest stage of production, one is faced with the problem of analyzing the collected information. It is relatively easy to develop software to analyze data from a single sensor, but when there are 10,000 devices to be processed, things get more complicated. Recent years have seen a lot of progress in the development of Big Data algorithms, which help to solve problems with large amounts of data.

Embedded systems have been developing at a very fast pace over the years, and there is currently no indication that their development has slowed down. They can be encountered almost everywhere. They take measurements, analyze data, display necessary information, control other components, protect against unauthorized access… and so much more. They are indispensable in virtually every industry, and in the future, humanity’s dependence on these devices will grow even more.