TABLE OF CONTENTS:

In an era when online shopping booms, brick-and-mortar shops face a daunting challenge. The CBRE report ‘Omnichannel trends in Poland’ shows that 75% of Poles shop via the internet at least once a month. What can retail chains do to compete with online shopping? In this case, technology, particularly artificial intelligence, may come in handy. If you’re interested in how AI enhances merchandising, this article is for you.

Merchandising, planograms, and displays are all common terms in retail. They often come with many surprises along the way and certainly a great deal of responsibility. Studies show that properly arranging goods on store shelves can boost sales by up to 30%!

What risks does merchandising pose to businesses that see it as a way to bolster their bottom line?

So, how do you ensure that the exposure aligns with the planogram guidelines in a way that realistically contributes to the anticipated sales increase?

Utilizing AI to automate the process of merchandising can help to boost efficiency. Furthermore, we have already executed several such projects for retail clients.

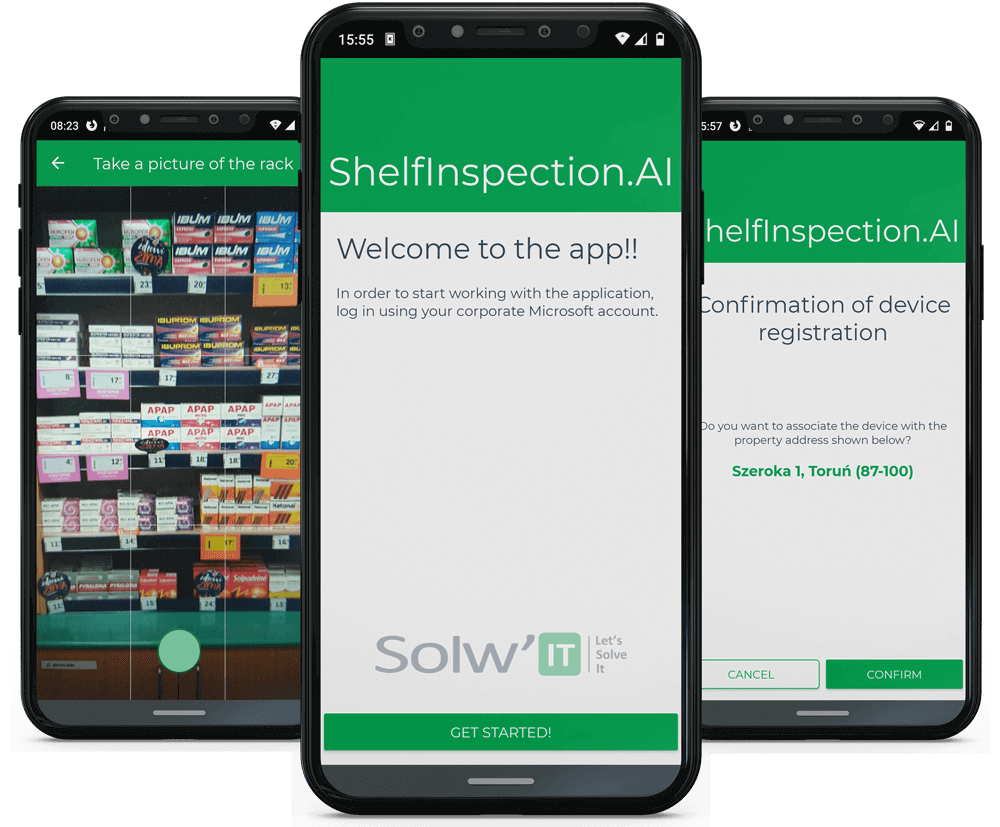

To improve the merchandising process in retail chains, we used the Shelf Inspection AI solution. In this case, artificial intelligence verifies the gear on the shelves through trained neural networks. After analyzing the images and comparing the product display with the planogram, we receive data and clear reports, enabling us to track where our product display stands in specific outlets. This solution also benefits businesses by eliminating the need for additional employees (auditors or sales representatives) who previously had to regularly check the positioning of products on shelves at all points of sale. So, how does it work? Keep reading!

Shop employees receive planograms with orders from head office. The app is used to take an exposure photo. With the help of artificial intelligence (AI) algorithms, the system analyzes the photograph content and instantly tells you whether products have been placed correctly. A staff member corrects the positioning until it is accurate, and then you are informed that the product is standing correctly.

AI recognizes the type and number of products and other items in the photo with a high degree of efficiency. It then compares it with the planogram.